CNC turning centers and lathes may seem identical, but they generally refer to slightly different machines. Lathes generally only turn while turning centers can be more advanced. These machines can be capable of facing, threading, knurling, drilling, boring, reaming, and taper turning. Horizontal CNC turning machines are more common, but vertical machines utilize gravity.

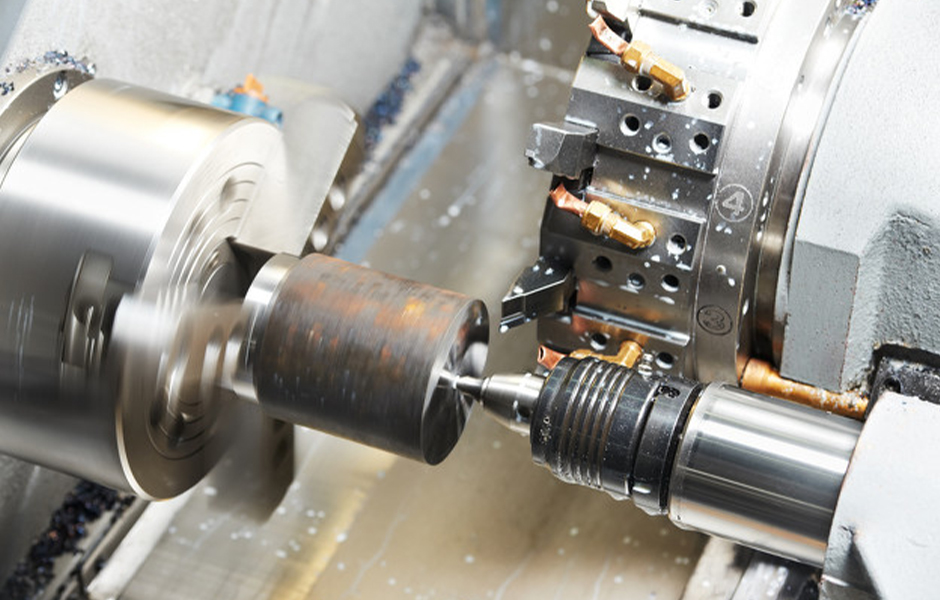

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret (shown center), with tooling attached is programmed to move to the bar of raw material and remove material to create the programmed result. This is also called “subtraction machining” since it involves material removal. If the center has both tuning and milling capabilities, such as the one above, the rotation can be stopped to allow for milling out of other shapes.

What are CNC turning’s applications?

Turning produces rotational, typically axis-symmetric parts with many features, such as holes, grooves, threads, tapers, various diameter steps, and even contoured surfaces. Parts that are fabricated entirely through turning often include components that are used in limited quantities, perhaps for prototypes, such as custom-designed shafts and fasteners. Turning is also frequently used as a secondary process to add or refine features on parts manufactured using a different method. Because of the high tolerances and surface finishes that turning creates, it is used for adding precision features to a part whose basic shape has already been formed.

CNC mills are primarily used to create complicated geometries, while CNC lathes create cylindrical or oblong shapes. CNC turning is usually chosen over a CNC milling or 3D printing because of its ability to make multiples of the same part extremely fast and from one stock piece of material.

CNC turning is used mainly with metals such as alloy steel, carbon steel, cast iron, stainless steel, aluminum, copper, magnesium, and zinc. However, the process can also be used to machine plastic parts and work with other materials such as ceramics, composites, thermoplastics, and thermosets.

The result of turning is a precisely finished product or an intricate part. Because these machines are so versatile, many industries use them, including automotive, electronics, aerospace, firearm manufacturing, sporting, and others.

CNC turning can produce plane surfaces and screw threads or, in the case of ornate lathes, three-dimensional products that are quite complex. They can be used on both small and large parts with extreme accuracy. The workpiece is typically held firmly in place by one or two centers, but the material can also be secured with collets or clamps.

Some examples of CNC turning applications are baseball bats, camshafts, bowls, crankshafts, cue sticks, signboards, musical instruments, and table and chair legs.